- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Refrigerated/Reefer Container Offshore Container Container House Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Cutting Machine Processing Machine Bending Machine Block Machine Other Machinery Motor Spare Parts

- Mechanical Products Miscellany Mooring Equipment Marine Equipment Vehicle Industry Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Power Distribution Automation Electrical Cable Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Plastic Pipes and Pipe Fittings Fiberglass Reinforced Plastic Pontoon System

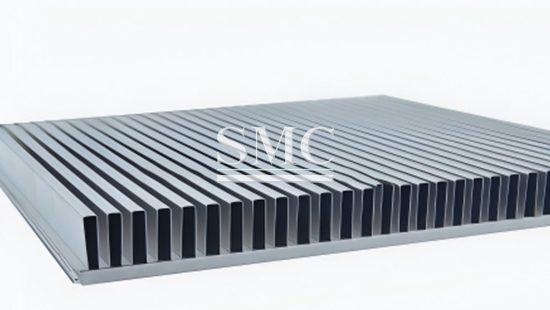

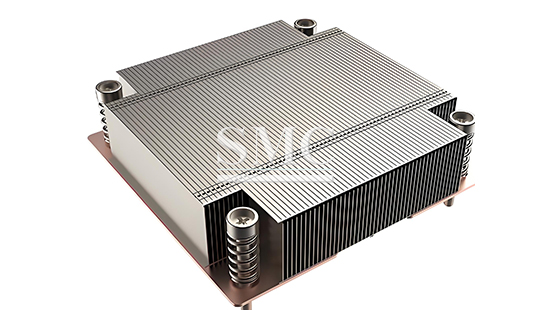

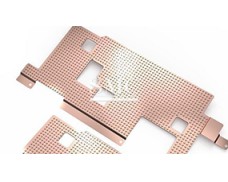

Aluminum Vapor Chamber Heat Spreader

Base Material: 6061/6063 aluminum alloy

Thickness: 0.4-3.0mm(customizable)

Working Fluid: Environmentally friendly hydrocarbon

Process: Vacuum brazing,laser weliding, precision etching

Surface Treatment: Anodizing, conductive coating, Ni plating

Our company specializes in precision-engineered aluminum vapor chamber heat spreaders, a revolutionary thermal management solution that combines lightweight design with high-performance phase-change cooling. Utilizing advanced vacuum brazing technology and capillary structure optimization, these vapor chambers achieve effective thermal conductivity of 200-350 W/m·K while reducing weight by 60% compared to copper alternatives - making them ideal for consumer electronics, LED lighting, automotive electronics, and portable devices.

Aluminum vapor chamber heat spreaders integrate seamlessly with existing heat sink designs while offering superior thermal uniformity. Their internal sintered wick structure and optimized working fluid enable efficient heat spreading in thicknesses as thin as 0.4mm, eliminating hot spots in high-power density applications up to 200W/cm².

Customizable in shape, thickness, and surface treatment, our aluminum VC solutions provide cost-effective thermal management without compromising performance. Achieve temperature reductions of 15-25°C while significantly lowering material costs and product weight.

Request thermal test reports or prototyping support within 24 hours - enhance your thermal design with lightweight aluminum vapor chamber technology!

Packaging of Aluminum Vapor Chamber Heat Spreader

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

here

for

price